Recent innovations in airless spray gun technology are having a big impact in the cabinet making and flat line wood finishing industries. Equipment engineers have made an atomization breakthrough to reduce the size of the material droplet and slow the speed of delivery for a softer impact on the surface.

You don’t need air pressure for the application, so there is less turbulence. The latest airless spray guns have dialed in on the combination of the velocity and size of the droplet so that your operator will have a smooth application with much less bounce and overspray and a higher quality finish.

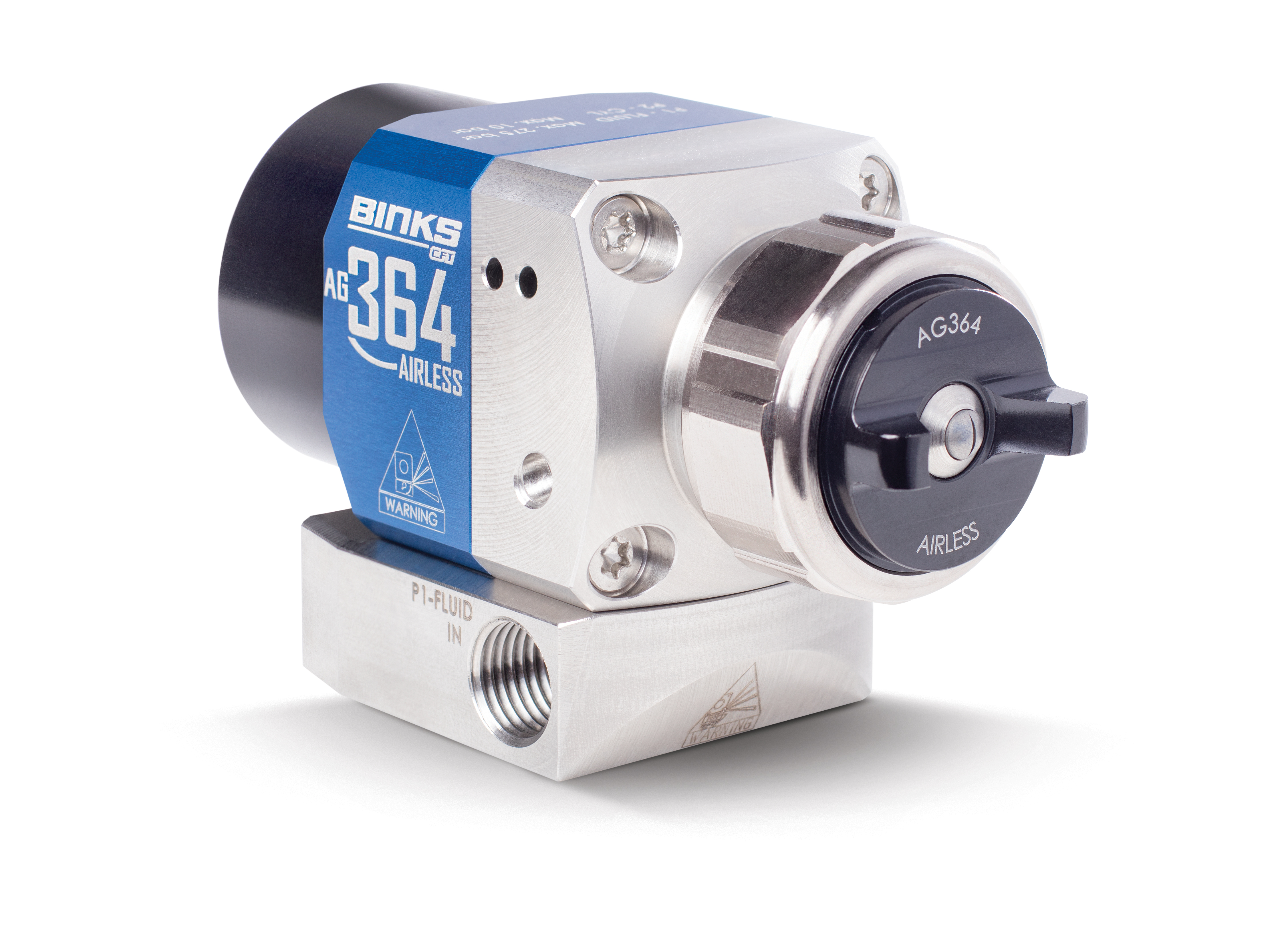

Leading cabinet makers and wood finishing companies have returned to using airless guns, even for staining operations. The top of the airless category, the Binks AG-364, has unmatched droplet velocity, which allows it to deliver:

Better transfer efficiency, which helps eliminate excessive paint waste and lengthy cleaning time

A softer high integrity fan pattern, which allows for the consistent application of materials to detailed profiles and surfaces

Airless Spray Guns Save Time and Costs for Cabinet Makers, Wood Finishers

When more of the paint is landing and staying on the surface, it provides a cascading series of benefits. The latest innovations in airless spray guns make them especially helpful for painting odd angles, inside corners, recessed panels and edges. The reduced overspray makes it easier to see through any glass to the inside of a spray cabinet.

Defects from overspray, dry spray and poor coverage will be substantially reduced, which will also lower rework costs. This solution also helps realize significant savings in:

CLEANING: An airless spray gun will reduce how often you clean and how much you have to clean up each time. There is less overspray to clean up on the substrate and equipment. One AG-364 client reduced cleaning time in one operation from 6 hours a day to 1 hour a day.

COATING: The softer droplet landing equates to a higher first-pass yield and significant improvements in efficiency. Our experts are confident that switching to an airless spray gun will reduce coating usage by 20 percent or more. Some clients have reported a drop in usage by 60 percent.

FILTER USAGE: Less material usage and less overspray means your filters are catching much less materials. Many clients have reported a reduction of 50 percent in filter use. One AG-364 customer had been replacing filters every two hours, and now is doing it every eight hours.

Breakthroughs and Versatility Provide Finesse Needed for Staining

Airspray has traditionally been more of a finesse application than airless, which made it the method of choice for applying stain. But with the breakthrough in atomization, along with the development of tip sizes and fan patterns, airless guns now provide the added depth in wetness required for staining and the versatility needed for many types of wood and finishes.

Large furniture companies now use airless for their staining. We will work with you to see if an airless spray system is right for your staining operation.

People Throughout Your Organization Will Share in the Benefits

The frontline operators will be champions for your switch to airless spray guns, but they will not be the only people in your company to notice. But let’s start with them.

OPERATORS: buy in because they can watch the machine run and don’t have to stop for cleaning throughout the day. The performance is predictable and adjustable, which means with the improved application efficiency, there are less variables for the operators to manage while the gun is on. Operators will immediately notice higher first-pass yields, and they will also notice the difference when they make adjustments to account for the viscosity, speed of gun, fluid pressure, and so on.

MANAGEMENT: notices less down time and material usage. They also will see an improvement in overall equipment efficiency and longer lasting equipment. In many cases, you will be able to reduce the number of guns you need or add to your capacity. One customer using the AG-364 was able to reduce their operation from eight guns to four.

PURCHASING: will need to acquire less material, have reduced disposal costs, and have more backup guns. The AG-364 also is easy to upgrade or transition to from air-assisted equipment as it uses the same pumps, fluid lines, and regulators and the same pressure ranges. Airless spray guns are available in dead head or recirculation manifolds. You can purchase components or a complete system.

Work With Spray Equipment & Service Center For Your Airless Needs

Another indirect benefit of switching to airless spray guns is that they are so efficient it will help you see other weaknesses in your operation. It can be a drastic improvement in your operation. For example, one customer using air assisted guns would operate from 1500 PSI up to 7000 PSI. They switched to the AG-364 and now can start at 100 PSI and never go above 600 PSI.

We can help you determine if an airless spray gun is the right solution for your operation. We also provide qualified technical support after the purchase and provide added value through:

ADVICE: Our experience, expertise, and approach work for you at every stage

SUPPLY: We have the right equipment and parts

SERVICE: We are just a phone call away (866-953-0526).