Find the Perfect Paint Booth for Your Needs

Spray Equipment offers a wide range of paint booth solutions to ensure a safe, clean, and code-compliant environment for your operation. Our booths are designed to meet your specific production needs and deliver several key benefits:

We offer various booth types and sizes to accommodate your specific needs and workspace. Contact Spray Equipment today to discuss the ideal paint booth solution for your business.

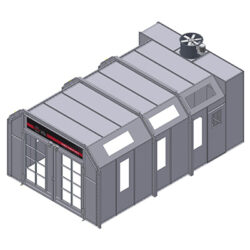

Our most popular booths, these are flexible, cost-effective solutions. The open-front design saves valuable floor space and makes it easy to move products and parts in and out of the booth.

The most cost-effective airflow style, crossdraft airflow offers reliable performance. Since there is no pit to dig, crossdraft booths are also easier to integrate into existing facilities.

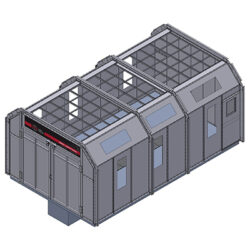

Generally accepted as the best airflow style for controlling overspray and contamination. Air flows vertically over the product and into the filtered exhaust pit in the floor.

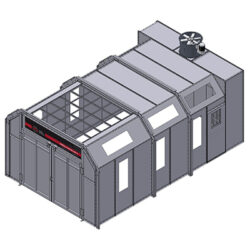

An economical solution for shops that aren’t able to install a pit. Air flows downward and is pulled into floor-level filtered exhaust plenums on and both sides of the booth.

A hybrid combining crossdraft and downdraft, air is introduced at the top of one end of the booth and is pulled across the working chamber into the filtered exhaust chamber at the rear.

These are designed for wet coatings with temperature and humidity control, regenerative thermal oxidizers and other abatement equipment for control of Volatile Organic Compounds (VOC).

These are extremely efficient for removing paint particles from the exhaust air, resulting in a cleaner painting environment for superior finishes, increased productivity and improved working conditions.