In manufacturing, sealants and adhesives are the hidden workhorses that hold products together. From the micro-dots in electronics to the structural bonds in aerospace components, these materials are integral to countless production processes. But for many shops, their application process relies on inefficient caulk tubes that slow down production and can eat into profits.

The shift to a professional supply system that utilizes drums of material, high-powered pumps, and specialized applicators can dramatically increase efficiency and reduce material costs. However, the path to these savings is often blocked by the high cost of entry. The specialized pumps required for these systems can be a major capital expenditure, with prices ranging from $10,000 to $20,000.

The common thinking is that a professional system is out of reach, reserved only for the largest manufacturers. But the reality is that the financial return on investment (ROI) can be surprisingly fast, making the upgrade a smart business decision for any operation that meets a certain volume threshold. This isn't just about saving money on materials; it's about optimizing your entire production line.

In this article, we'll break down the numbers with a real-world example and explore how investing in sealant and adhesive dispensing equipment can benefit both your bottom line and your employees. We’ll demonstrate that while the upfront cost is a consideration, the long-term benefits in efficiency, material savings, and operator satisfaction can far outweigh the initial investment.

A Real-World Example for Converting from Caulk Tubes to a Supply System

Let's dive into a real-world example to see how the high upfront cost of investing in sealant and adhesive dispensing equipment can be justified by significant long-term savings. A leading manufacturer in a niche recreational category was using four tubes of adhesives for every product they turned out. That added up to about 250 tubes per week.

One small bucket of adhesive material in a professional supply setup could be the equivalent of about 60 caulk tubes. A large drum of adhesive material could be equal to about 600 caulk tubes. You could buy the adhesive material for a large drum with a manual dispenser and hose for half the cost of the tubes. But the savings in materials only occurs if you invest in the right equipment. In this case, the initial investment was about $14,000.

The ROI for sealant and adhesive dispensing equipment is pretty easy to calculate. It revolves around how often the operation is using adhesives, and how much volume. It will not make sense to convert for a shop using two tubes a day. But if they are using two per hour, it might be worthwhile.

For many industrial finishing companies that meet a volume threshold, there is about a 24-month ROI for the professional supply system. For the recreational manufacturer, it was about a 14-month ROI.

Operators Notice When You Invest in Equipment That Helps Them

ROI is more than a mathematical equation. It’s an investment in your business and people. The benefits of using a professional supply setup include:

Faster and more accurate application

Materials savings

Higher quality mixing as opposed to hand mixing

Operators also notice that the company is investing in them and new equipment. The application with a professional supply system is physically easier versus the caulk tubes, which are not ergonomically friendly and can lead to repetitive-motion injuries.

The training and adoption of a professional system is pretty simple. There is a trade-off of more low-level maintenance for professional supply systems, but most operators gladly accept it because the sealant and adhesive dispensing equipment makes their jobs so much easier.

Why you should work with Spray Equipment & Service Center

Navigating the many variables in selecting the right sealant and adhesive dispensing equipment can be a bit overwhelming. This is precisely why you should consider consulting with the experts at Spray Equipment & Service Center. We learn about the nuances of your operation, your goals and objectives, and leverage our expertise to match you with the right mix of tools, applications, and processes.

In many cases, operators are converting to a professional supply setup for sealants and adhesives because they have a new customer or a process requires it. For example, many manufacturers are switching to epoxies and multi-component material mixes because they often cure faster than legacy materials. This can improve overall cycle times.

Operators often don’t know enough about the material they are working with, which impacts which applicators should be used. There are also additional considerations if you are working on two-component mixes of adhesives or working with epoxies. One of the best arguments for a professional system is that two-component mixers have a proven ratio accuracy of 99%, much higher than hand mixing.

Let’s look at some options for getting started with your professional supply system and the basics for ongoing operations.

Equipment to Get Started With a Professional Supply System

A Spray Equipment & Service Center expert can help you determine the best choices for your first system. Here are some products to check out.

Supply Systems & Pumps

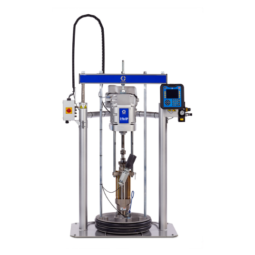

Graco supply systems and pumps for sealant and adhesive dispense support single-component (1K) materials at ambient temperatures for low- to high-viscosity materials. Supported container sizes range from 1-gallon pails to larger drums from 5 to 300 gallons. They are designed with innovative features plus advanced pump, motor technologies, and optional tandem operation capability.

E-Flo SP Pumps & Supply Systems: Evolved from our proven pneumatic pump technology, electric sealant and adhesive supply systems, and pumps provide improved control strategies for better performance and higher efficiency.

Check-Mate Pumps & Supply Systems: The pneumatic supply systems and pumps reliably deliver one-component sealants, adhesives, and other medium to high-viscosity materials from pails or drums to metering and dispensing systems.

Meter, Mix, and Dispense Systems

Graco’s PRX solutions handle extremely viscous and abrasive two-component sealants and adhesives. Their patented first-in-first-out (FIFO) fluid path keeps materials from blocking and curing inside the pump. The unique coatings and fluid path geometry resist wear from abrasive materials.

PR-X Fixed Ratio Solution: The fixed ratio model produces precision and repeatability with every bead, dot, and pattern. Standard and custom configurations allow for flexibility in raw material supply and delivery.

PR-Xv Variable Ratio Solution: The variable ratio model offers the extreme variability needed for precise meter, mix, and dispense of two-component adhesives and sealants. Base purge minimizes mixer consumption and material waste.

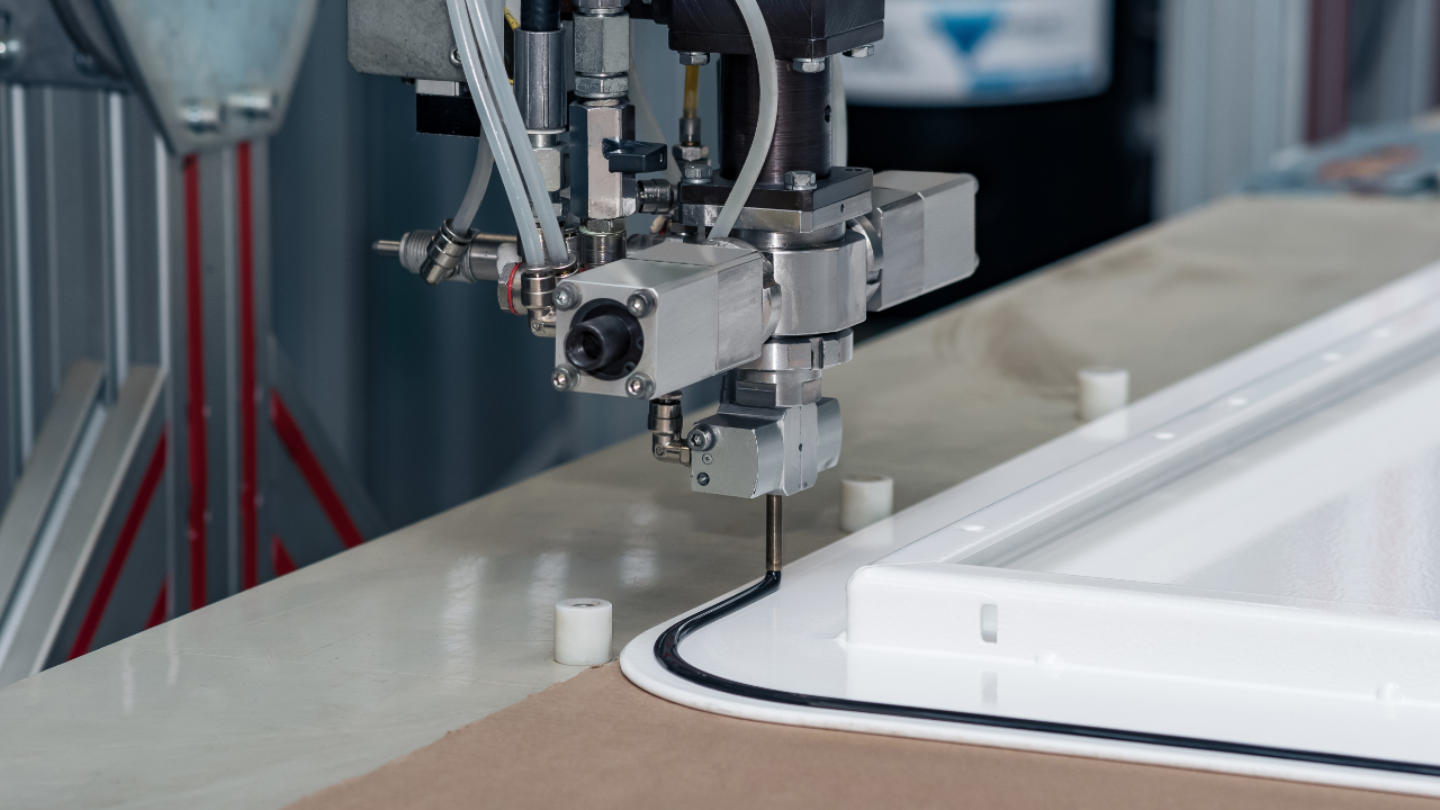

iQ Dispense Valves

Graco’s iQ Dispense Valves deliver long-lasting and dependable performance for single-component sealant and adhesive dispensing applications. The iQ series features a compact and lightweight body for high production applications, a durable design and components to improve life cycles and minimize maintenance costs, and three models to make it easy to customize to your application.

Other sealant and adhesive products are available in our online store, including parts, accessories, and repair kits.

Selecting the Right Sealant and Adhesive System for Your Operation

Spray Equipment & Service Center has supplied industrial finishing equipment to many North American businesses for more than 50 years. Our experts help you select the right sealant and adhesive dispensing equipment for your operation. We also provide qualified technical support and added value through:

Solutions Expertise: We listen and craft solutions to fit your unique business needs and goals.

Relationship-Focused Approach: We build trust by being responsive, meeting deadlines, and working hard to meet your highest expectations.

Industry Leadership: We have talented, experienced professionals at your service, here to keep your business as simple and profitable as possible.

We have the right equipment and parts in stock when you need them, and we are just a phone call away (866-953-0526).