Maximum performance for your air spray paint gun operation is all about transfer efficiency, which comes from creating the best atomization possible. Even with the proper spray gun setup and selection of air cap, nozzle and tip, there are many variables that will impact how a stream of fluid breaks down into the tiny droplets that you are spraying onto a surface. It’s a nuanced balance of air pressure and fan width, which means finetuning the operation varies greatly with the technology.

For example, with an air spray gun, your adjustments begin by finetuning air pressure. With an airless spray gun, you begin finetuning the pattern through fluid pressure and tip size.

Having many variables to choose from is why expert help is so valuable in adjusting your spray guns, hoses and pumps.

We are eager to help you get the most from your investments in equipment. We provide qualified technical support after your purchase and can help you, remotely or on site, with parts and rebuild suggestions. We emphasize relationships and a consultative approach for helping you develop best practices for your operation in areas such as:

Powering up, loading and pressurizing

Powering down, depressurizing and purging

Cleaning and storage

Tips for Adjustments With Your Air Spray Paint Guns

Keep in mind that when it comes to fluid adjustments with your air spray paint guns, more is not always better. This can seem counterintuitive, given that your goal is to spray the largest volume of paint with the least amount of overspray. If you are trying to push too much paint through the gun, you will quickly reach a point of diminishing returns with flow. It will impact the rate of atomization and lead to waste and uneven quality. It also will add to wear.

We can help you learn the nuances of the three areas to adjust on your spray gun:

Pattern: If you have reached the maximum or minimum fan opening setting, you may want to go to a different air cap.

Fluid: The more you open the fluid adjustment, the more air is required to fully atomize the material.

Air pressure: More pressure can lead to diminishing returns. Atomization air should be adjusted to achieve the best quality.

Another factor that impacts quality with air spray guns is ergonomics. Some guns are lighter or have an easier trigger pull, and some are heavier, which can lead to operator fatigue and a reduction in quality. Some operators may not be aware of options. Let us help you find the gun that best fits your hand.

Tips for Adjustments With Your Hoses

Hoses should not be an afterthought for your spray gun as they have many indirect impacts on the overall operation. For example, dragging an unnecessarily long fluid hose around a worksite not only creates a tripping hazard, but it also wears on the hose and contributes to material waste and purging time when the material is flushed out.

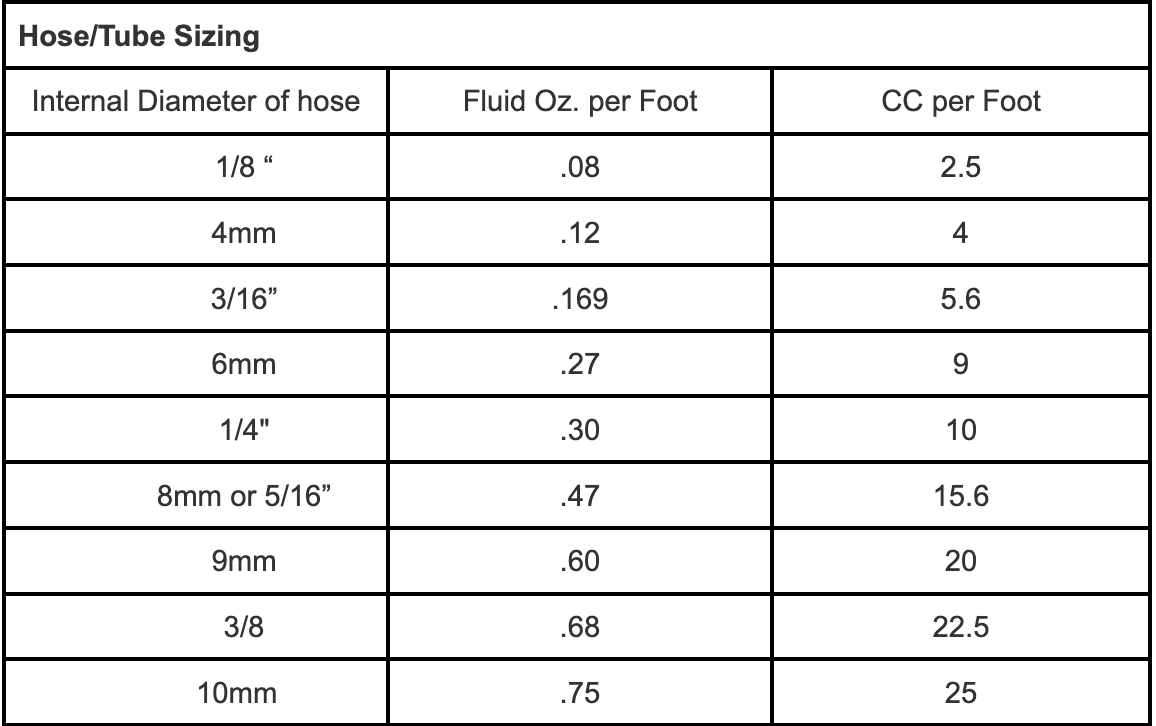

The right fluid hose size depends on volume of fluid desired and the spray gun capacity (see chart). Generally speaking, the higher the CFM requirement of your spray gun, the larger the diameter air hose you’ll need. It’s also important to select the right hose for chemical compatibility with the material supply – resins with an acid catalyst might require a hose with a Teflon core, or resins that don’t have a catalyst may need a moisture-sensitive hose. The connections on the hose can vary as well.

As far as adjustments go, you may have alternatives to whatever hose is installed. You might also consider buying hose material in bulk so you can make customizable lengths on the job site and use field-installable fittings.

Tips for Adjustments With Your Pumps

Once on the job site, the pump adjustments you make for a specific operation might be based on:

Viscosity of the material

Fluid pressures required for the specific applications

How far the gun is from pump

Circulating versus dead-end systems

Another consideration on the worksite is the number of applicators or spray stations that you need to supply. One pump might be able to serve multiple guns. You might be able to help future-proof your setup with a bigger pump. You may also be able to rebuild pumps, which means less frequent purchases.

Spray Equipment & Service Center Can Help Your Get More

We have a large volume of spray gun parts and accessories on hand from all of the major brands. We have whatever you need in our huge inventory of spray gun parts and accessories.

We are your trusted partner for all things Spray as we provide added value through:

Advice: Our experience, expertise and approach work for you at every stage

Supply: We have the right equipment and parts

Service: We are just a phone call away (866-953-0526) or here for a live chat

Let us put our talent, technology and service to work for you. Let’s talk.